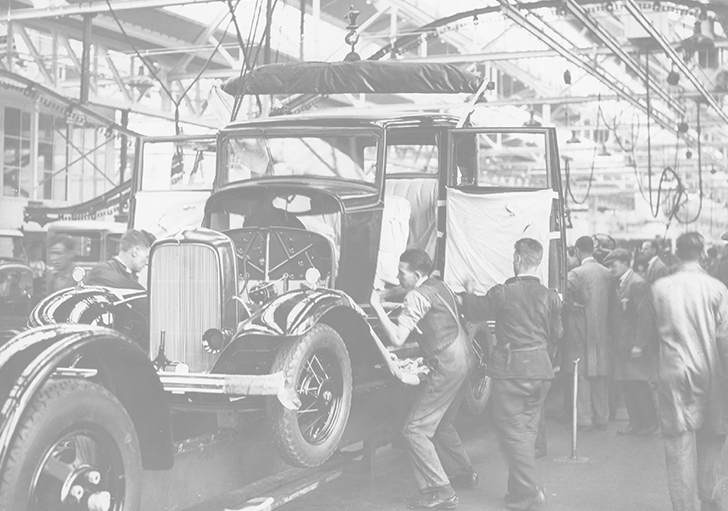

UNITRUCK is a leading brand dedicated to providing high-quality filters for heavy vehicles. Since its establishment, the brand has gained widespread recognition globally for its exceptional product quality and technological innovation. The history of UNITRUCK dates back to the early 20th century, during a time when Germany was renowned for its industrial revolution, characterized by rigorous manufacturing standards and innovative capabilities. UNITRUCK emerged from this backdrop, with a core mission to deliver the most reliable filtration solutions for heavy vehicles. Initially focused on producing filters for trucks, buses, and construction machinery in the European market, the brand steadily enhanced the filtration efficiency and durability of its products to meet the growing market demand.

In the 21st century, UNITRUCK rapidly expanded into global markets, particularly in Asia, North America, and the Middle East. As globalization accelerated, UNITRUCK Germany established a worldwide production and distribution network to ensure consistent high-quality standards across its products. The brand’s core value—“BUILT FOR RELIABILITY”—permeates every aspect of its product design and manufacturing processes.

Product

Employees

Factory Area

Customers in countries

Quality

Quality

Rigorous Testing, Safety in Every Detail Services

Services

Your satisfaction is the driving force behind everything we do Future

Future

Shaping the Future Through Innovation

We are partners of OE manufacturers; we support them all the way from the design stages through supply, creating highly reliable and customized products, within the given timeframe. We are able to provide our experience, careful advice and extensive production flexibility.

FONHO is equipped with comprehensive filter testing facilities. During product development and mass production, various performance tests are conducted to ensure the stability and high performance of the filters. The following is the FONHO product performance test list:

- Filter pressure resistance test: Can withstand pressure over 2.5 MPa.

- Filtration efficiency and dust capacity test.

- Filter element collapse test.withstands pressureover 1.0MPa.

- Filter element collapse test: Withstands pressure over 1.0 MPa.

The FONHO air dryer cartridges solve the problem. Compared with most manufacturersin the world, FNHO air dryers are featured with following advantages:

- High resistance to pressure and pulsation

- Quality desiccant with highest drying performance, anti-abrasion and water-resistance

- lmproved oil separation

- Strong sealing function

- Great rigidity to vibration

- Excellent corrosion prevention and protectionEnsured braking reliability

- Long service life

- Lower service cost and shorter downtime

In the demanding world of heavy-duty vehicles, filtration isn't just a component — it's a critical defense line. Our advanced filtration systems are engineered to withstand extreme environments, ensuring optimal engine protection, improved fuel efficiency, and extended vehicle lifespan.

We deliver high-performance solutions tailored for trucks, construction machinery, agricultural equipment, and more — built to perform under pressure, so your fleet never stops.

Our customers sit at the core of our business model and all our processes revolve around the needs and demands of our customers, ensuring high-quality customer servicing.

The Research & Development team and Quality division set up by UNITRUCK is to focus efforts in the direction of Applied Research, which is aimed at facilitation of improvement of the current product line improvement of operating procedures and development of future products.The R&D helps the organization align itself proactively to the ever-changing market dynamics, customer preferences, and technological advances.

PRODUCTION -SALE RATE

95%

PRODUCT MODEL

8000+

PRODUCTION LEAD TIME

30-45 days

PRODUCT INSPECTION

100%

NEW PRODUCTS DEVELOPMENT

30-80 days

ON TIME DELIVERY RATE

≧98%

CUSTOMER SATISFACTION

≧99%

IATF 16949 AND CE

| 浙ICP备2023022974号-1 |